In addition to a number of standard devices, J. Thielmann has several special variants in its product range. This allows us to match customer requirements, generating added value. The advantages are simplified plant construction and equipment installation, as well as productivity, availability, equipment reliability and process reliability within the welding process. Our large range of different solutions shows that we are a partner who takes its customer’s requirements seriously and is therefore constantly developing.

Special Solutions

Cleaning a stationary torch

consisting of

- Torch-Cleaning-Station BRG for stationary torch, Item No. 200664

- Swivel device TSB for BRG, Item No. TSBxxxx

Torch-Cleaning-Station BRG for a stationary torch

Item No. 200664

Characteristics

- Automatic, electro-pneumatic program sequence

- Cleans nozzle and spray anti-spatter fluid in one position

- Sprays anti-spatter fluid via robot output

- Adjustable gas nozzle fixing piece for different gas nozzle diameters

Robot inputs and outputs

- Robot input

– Limit switch, gas nozzle not clamped

– Limit switch, motor/reamer up - Robot output

– Start cleaning cycle

– Spray anti-spatter fluid

Technical Data

- Cycle time: ~ 3.5 seconds cleaning

- Quantity of anti-spatter fluid: 1 litre

- Voltage: 24 V DC

- Current: 0.25 A

- Control via Profinet

- Pneumatic connection: 6 bar/87 psi

Swivel device TSB for BRG

Item No. TSBxxxx

Characteristics

- Swivel clockwise/anticlockwise

- Application with additional wire cutting function possible

- Design of the TSB according to torch position/cell layout

Robot inputs and outputs

- Robot inputs

– Start position

– Cleaning position - Robot outputs

– Swiveling

– Safety function

Technical Data

- Cycle time: ~ 6-7 seconds

- Voltage: 24 V DC

- Current: 0.5 A

- Control via Profinet

- Pneumatic connection: 6 bar/87 psi

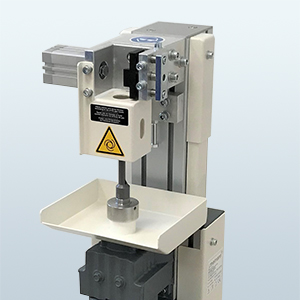

Torch-Cleaning-Station BRG-1000 electrical

Item No. 1003xx

Characteristics

- Electro-pneumatic program sequence

- Cleans nozzle and spray anti-spatter fluid in one position

- Sprays anti-spatter fluid via robot output

- Patented spraying system

- Adjustable gas nozzle fixing piece for different gas nozzle diameters

- Motor as the most important energy consumer of the unit is not pneumatically driven, but electrically

Robot inputs and outputs

- Robot inputs

– Limit switch, gas nozzle not clamped/clamped

– Limit switch, reamer up/down - Robot outputs

– Start cleaning cycle

– Spray anti-spatter fluid

Technical Data

- Cycle time: ~ 4 seconds

- Quantity of anti-spatter fluid: 1 litre

- Voltage/current 380 V/0.4 A

- Voltage/current 24 V DC/0.3 A

- Pneumatic connection: 6 bar/87 psi

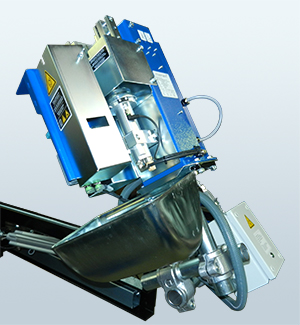

Laserhybrid-Cleaning-Station LHR-3

Item No. 300356

Characteristics

- Automatic, electro-pneumatic program sequence

- Cleans a laser hybrid welding head with filler rod and optics for seam tracking

- Custom design as Profinet version

Robot inputs and outputs

- Robot inputs

– Various, depending on function to be defined - Robot outputs

– Various, depending on function to be defined

Technical Data

- Cycle time: ~10 seconds

- Voltage: 24 V DC

- Current: 0.6 A

- Pneumatic connection: 6 bar/87 ps